Following a Surveyor Conference coordinated by The Church of England, CorkSol were invited to present our solution to the Diocese of Sheffield to help them improve the energy performance of one of their vicarages.

The vicarage, a stone built property with existing internal features, was cold with poor energy efficiency. As it became void, the Diocese of Sheffield wanted a solution that offered flexibility and could address the issue of heat loss with a sympathetic appreciation of the building type, heritage and existing features.

James Erskine, Specification Sales Manager at CorkSol explained, “The property had high bills because of its poor energy efficiency. They wanted to be able to improve this and the EPC performance with a solution that didn’t involve having to hack off the existing wall substrates. On top of this, the front elevation is stone whilst the remaining three are covered in rough cast, so we needed to be able to take this into account and use the same solution internally and externally.”

The proposed solution was to use CorkSol SprayCork externally on the rear and side elevations, whilst using it internally on the exterior walls with an overskim of breathable plaster.

To demonstrate the ability of CorkSol to deliver a high performance solution that would meet the requirements, we employed Build Test Solutions to independently test the installed performance of SprayCork. Air permeability and U-value measurements were carried out at the vicarage in March and June 2024, before and after the application of the SprayCork.

The Testing

The measurements carried out by Build Test Solutions were:

Pulse measurement of air infiltration:

This is a measurement of the air infiltration between outside and in. Air infiltration is unintended air leakage via holes, gaps and cracks in the building fabric and does not include deliberate ventilation.

Heat3D U-value measurement of the external wall:

The U-value of a building element defines its heat loss rate per degree of temperature difference between inside and out. A low U-value means less heat loss and better performance.

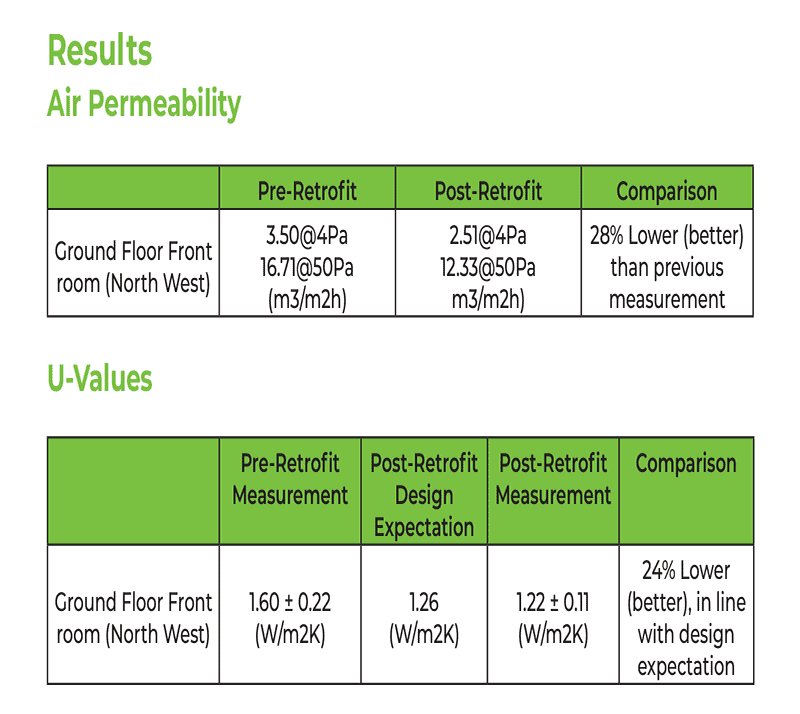

Pre-retrofit values were taken in late March and repeated in June after two layers of SprayCork had been applied to the property and given time to dry. U-value measurements were carried out in the northwest ground floor room, which was to be treated both internally and externally and on the first floor, which has a single external layer applied. The measurements were taken at the northern façade. Air permeability of the building as a whole was measured, as well as the downstairs front room which was receiving the two layers of SprayCork.

The Results

The U-Value measurements showed a 24% reduction (improvement) for the front room. This performance improvement is in line with the expected performance improvement calculated based on the thermal properties of the SprayCork insulation and therefore provides a successful demonstration of the product in a real-world application. The air permeability measurements showed a 28% reduction in air permeability in the front room. This is a significant improvement.