Following the need to improve the energy efficiency of their property, a York based family opted to use SprayCork on the exterior of their house.

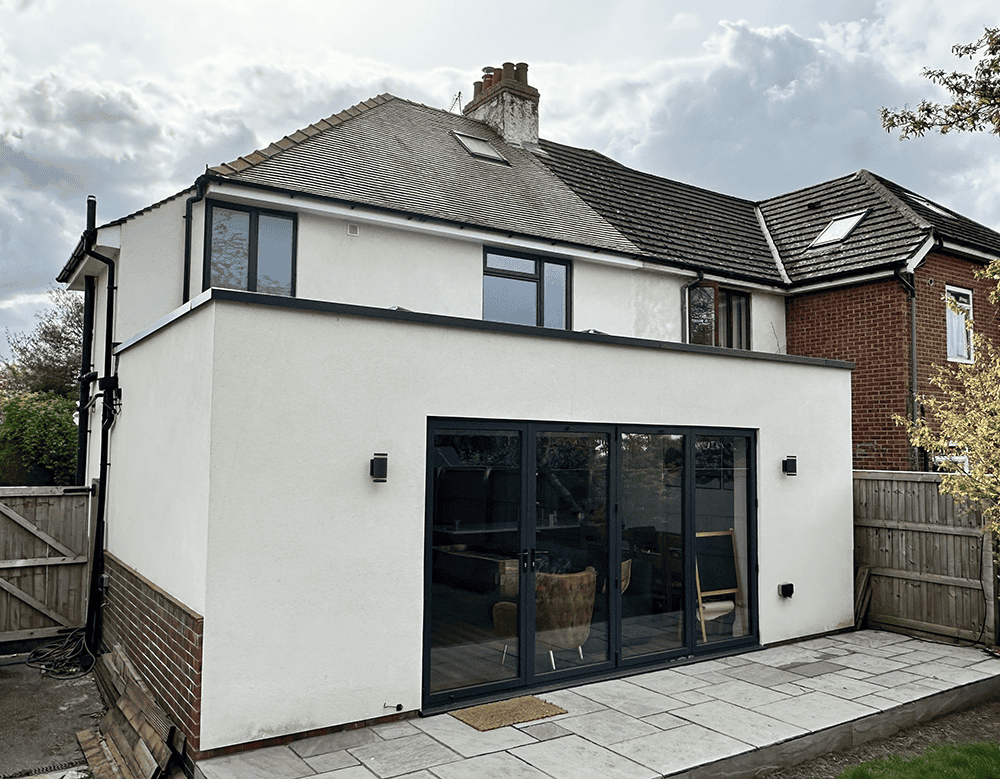

The 1930's semi-detached property in York was constructed with solid brick, with insufficient render to the front and side. The rear extension was covered in cracked and discoloured monocouche render, further contributed to heat loss.

Following a comprehensive assessment, the property’s Energy Performance Certificate (EPC) displayed a score of D (60), indicating a relatively low energy efficiency level. However, the EPC also suggests that the property could achieve the potential C rating (79) by addressing the walls of the property as they did not hold a cavity.

Testing carried out by Aico identified that there was a high heat loss risk within the property. It also highlighted the average Time to Lose 1 degree (TTL) of 28 minutes, indicating a quicker rate of heat loss. The TTL value can be used to provide a comparison of heat loss across different homes, and is calculated by utilising both internal and external temperature conditions. This provides understanding about how quickly a room is losing heat to the outside world.

The Solution

Considering the lack of wall insulation of the property, improving the fabric of the building would increase its energy efficiency. The property's design presented specific challenges to this, as the first metre from the ground is exposed brick before stepping in slightly and becoming rendered. As such, any external wall insulation system of 100mm—150mm would cover this, which wasn’t desirable. Furthermore, all the windows of the property would have to be removed and reinstalled. CorkSol Independent Applicator, JMB Plastering Specialists, proposed using SprayCork on the property to improve insulation, reduce the need for removal of existing fittings, and enhance the property's appearance. As the existing monocouche substrate was sound, SprayCork was simply applied as an overspray. For the other areas, the process involved removing existing render, sealing and priming the brickwork ready for spraying.

The Outcome

The property was monitored for two months following the SprayCork application in order to evaluate the effectiveness of the solution. These results were then compared to the data taken before the application, using the HomeLINK dashboard.

The results showed a significant improvement in the property’s energy performance. Heat loss risk had changed from high across all three rooms to medium in 2 and low in 1. In line with this, the TTL 1 degree had increased from 28 minutes to 53 minutes - a huge increase of 25 minutes. This demonstrated a huge improvement in the energy efficiency of the home.

To find out more about how CorkSol can help make your project cosier, healthier and more attractive, please contact us.